AUSTIN COUNTY HISTORY

The word acme is familiar to many in Texas, even far beyond Austin County.

In fact, it’s a word probably best remembered from the Road Runner & Wile E. Coyote Looney Tunes cartoons, debuting in 1949, which comically featured an array of fictional Acme Corporation products that almost always failed to work.

That’s ironic and funny, too, for the word Acme actually means something perfect: something that is the best, of highest quality, and most successful.

In fact, the word acme predates that cartoon by as many as 4,000 years, for it comes from the ancient Greek word akmē, meaning “summit or highest point.”

So, it seems only fitting that the 133-year-old, Texas-based company Acme Brick, a pillar of high-quality production, with its large San Felipe Plant brick manufacturing plant in Sealy, Austin County, Texas, would feature this popular, strong, ancient word in its name.

FOUNDING FATHER

According to writer and historian Bill Beck, author of a book on the history of Acme Brick, in the late 1800s, a visionary Dallas-area merchant named George Bennett recognized a growing demand for construction materials in the state, as Texans moved out of the frontier stage and cities emerged. Beck goes on to explain that “with locals demanding substantial lodging other than log cabins, Bennett acknowledged the need for a successful pressed brick factory in Texas.” And so, in 1891, Bennett established Texas’ first Acme Brick Company plant, (originally named Acme Pressed Brick Company) near Milsap Texas, just west of Weatherford.

SEALY’S SAN FELIPE PLANT

Then, 40 years ago in 1984, work to establish Acme Brick’s San Felipe Plant in Sealy quickly got underway, and by the time the first brick was produced there in 1986, the local plant quickly became an integral part of Austin County’s story.

Today it continues to have a positive highly-sustainable impact on the local economy and to enhance area communities. Acme bricks have also benefited commercial and residential structures throughout Texas and across the entire nation with beauty and stability.

So, looking at the big picture, Acme Brick’s impact as a Texas titan in the brickmaking industry spans 133 years THE HANDSOME, ORNATE AND HISTORIC ADOLPHUS HOTEL IN DOWNTOWN DALLAS WAS MADE USING ACME BRICK.

and close to a half-century in Austin County alone.

AUSTIN COUNTY CONNECTION

But what brought Acme Brick to Austin County? The answer is simple: Demand.

By the early 1960s, as urban sprawl accelerated the growth of the Greater Houston area, a singular plant could not keep up with the demand for brick for commercial and residential buildings, according to historian Bill Beck.

“That’s when Acme management began to seek a new site near Houston suitable for high-volume brick manufacturing.”

“The hunt began in 1982, with an extensive surveying program to locate a large enough supply of suitable natural clays to support several decades (or more) of sustained brick production.

Acme associates investigated sites in Austin, Fort Bend, Grimes, Harris, Lee, and Washington counties – all of which contained alluvial clay deposits from the Brazos River. After drilling 343 holes and evaluating 1,655 samples over a 9-month period, they found what they were looking for, at two sites in Austin County,” says Beck. “Four test runs of brick made from clay at these properties confirmed their suitability – and from there it was off to the races.”

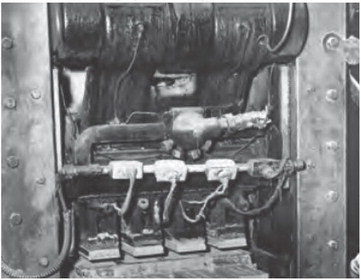

According to Beck, in 1984, Acme began preparing the plant’s location and requested bids from brick manufacturing equipment from American and European companies, ultimately selecting the Germany company called Lingl. A particular challenge they faced was the high moisture

“Within two years, the plant’s output was sold out – which is saying something since its opening capacity was 65 million bricks per year. ”

— Britt Stokes Director of Marketing Acme Brick Company content of the clay they would use. Most bidders felt that the “mud” was unsuitable for brick manufacturing, but the Lingl engineers found a way to make it work, and the final product was flawless.

Britt Stokes, the Director of Marketing for Acme Brick Company today, explains that Austin County’s San Felipe Plant’s first shipment of brick – a dark reddish brown, for residential use – came off the line in July 1986, and a formal grand opening of the plant was held that year on October 20.

There, Acme hosted contractors, architects and city officials from Sealy, Houston, San Felipe and Bellville, as well as area county officials, financial leaders, school officials, citizens, and employees. Activities included a golf tournament at Stephen F. Austin State Park, horseshoe pitching, brick tossing, a ribbon-cutting ceremony and plant tours. At its opening, the San Felipe Plant was the most automated brick manufacturing facility in the United States.

“Within two years, the plant’s output was sold out – which is saying something since its opening capacity was 65 million bricks per year. An expansion just five years later raised annual capacity to 100 million. And in the years since, capital improvements have kept the plant in what Acme’s founder would call ‘jam-up’ shape – and a pillar of Austin County,” says Stokes.

Today homes throughout Texas and stately buildings made from Texas’ own Acme Brick, like the unparalleled Adolphus Hotel in Dallas, stand tall, handsome, and sturdy, thanks to the hard work and expertise of Acme Brick manufacturers in Texas, and especially those proud of their time, toil, and skill in production of bricks at Acme’s San Felipe Plant in Austin County.

HISTORY OF BRICKMAKING

Brickmaking predates the great civilization of the Tigris-Euphrates River Valley, says historian Bill Beck, and is considered one of the oldest industries known to man. He writes that the use of bricks in American buildings came from England, and following the Revolutionary War, domestic production of brick increased as brick became more general in construction.

The first U.S. brickmaking patent was issued on May 15, 1800, Beck’s book explains, and “the number of patents increased over the next few decades, with new apparatuses including kilns and dryers being invented throughout the first half of the nineteenth century.”

“After the Civil War, American industry expanded at a tremendous rate, with brickmaking keeping pace with the universal trend toward increased production. In the United States alone, the number of establishments manufacturing clay products jumped from 2,121 in 1850 to 3,959 in 1870,” says Beck. That is why George Bennett was wise to establish Acme Brick in Texas – a testament to “aggressive leadership, dedicated and loyal employees, and dependable and reliable products,” he says.

“When Bennett incorporated the Acme Pressed Brick Company, there were literally thousands of brick companies nationwide. Today, approximately sixty remain. When you compare those two figures, it becomes clear that the hardworking men and women of Acme Brick Company have made that one-in-several-thousand difference,” according to Dennis D. Knautz, former president and CEO of Acme Brick. Today’s president and CEO is Ed Watson.

Today the Austin County San Felipe Plant is home to about 100 associates working at the plant, all dedicated to creating strong, beautiful, substantial bricks for use in homes and companies everywhere.

BUILT TO LAST

There is pride in the Acme family’s work and in their products at the San Felipe Plant in Austin County, and their product’s impact is as positive and far-reaching into the future as its long hard-working history. In fact, Assistant Director of Marketing of Acme Brick Company in Fort Worth, Matt Fels, is quick to point out that almost every house that has brick on it that was built in the Houston area since the late-1980s can trace its lineage back to Acme Brick in Sealy.

Bricks are built to last, and for 40 years the Acme Brick San Felipe Plant in Sealy has stood the test of time, providing jobs, economic stability, growth, sustainability and quality product to Austin County and all of Texas. Fortunately, its future looks just as strong.

Comment

Comments